Enamels can be supplied in different shapes and forms, depending on the requirement and the production process that uses the enamels. Enamels can be supplied in the shape of the frit, which is a semi-finished product that usually comes in the granule form. Frits are usually mainly made from SiO2 and B2O3. Enamels can also be supplied in the powder form, which is usually the frit that was milled. Diveng also supplies electrostatic enamel powders, which are usually the powder enamels that have been treated with polisiloxane and RTUs, which are often mixed with water and applied as the ground enamel.

Black Colour:

1. The black frit is loaded into the milling machines

2. During the milling, black enamel powder, which is sucked out of the milling machine with the air, is produced. The powder goes through the sieve – powder of the right size goes to the next step, while the larger particles go back into the machine for further milling.

3. The powder of the right size is then treated with polysiloxane that makes it applicable for the electrostatic application.

4. The steel parts are treated by degreasing, then dried with ultraviolet.

5. The black powder that was produced from the milling is then sprayed electrostatically, with the electrostatic spraying guns

6. The parts with the powder enamels move to the oven

7. The parts then spend a relatively short period of time in the oven, where the temperature is 820 - 830C.

8. In the end, the parts are cooled and then moved to the production line for the assembly.

White Colour:

In contrast to the darker colours such as black, grey and anthracite, lighter colours such as beige and white are sometimes applied with the ground enamel. In this example, we will use the ground enamel in the RTU form.

Preparation of the ground enamel.

1. RTU, which usually come in the powder form is unpacked and mixed with water.

2. Sometimes extra materials are added to the mixture, to ensure the right consistency, but usually just demineralized water is used.

Preparation of the cover enamel.

1. The process is the same as with the black frit. It starts with the white frit that is loaded into the milling machine, which results in turning the frit into the powder enamel.

2. The powder enamel is then treated with polysiloxane, to make it suitable for the electrostatic application.

Application:

1. The steel parts are degreased and dried

2. The ground enamel is applied. In this example, the ground enamel mixture is sprayed with the electrostatic pistols.

3. The steel parts, covered with ground enamel, are dried, using ultraviolet

4. The cover enamel powder, which was obtained by milling the white frit is applied on the parts

5. The component parts then go to the ovens and are heated at 820-830C

6. Finally, the steel parts are cooled and moved to the production line for the assembly.

In the example above, the typical thickness of the ground enamel is 60 microns and the total thickness after the application of the white enamel powder and firing is 150-180 microns. For single enamel applications, namely for black, dark grey and anthracite colours, the total thickness after firing is around 80-120 microns.

It is important to mention that the example above is just one way of applying the enamels. It is quite common for the users of enamels to have applications that include 2 coatings and 2 firings, have a difference in terms of dry and wet application, as well as have the requirements for the acidity resistance that can range from B to AA. Some frits and enamels also have a higher firing temperature that can reach up to 1200 C. The use of the enamels also highly depends on the equipment that used, specifically the ovens and application equipment which can include electrostatic pistols or traditional application method.

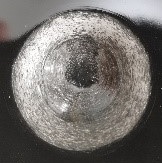

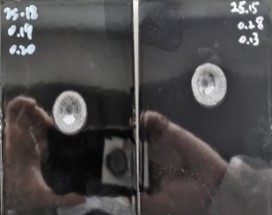

Diveng works closely with the leading European and Asian enamel producers and its customers to provide a tailored and cost-efficient solution that satisfy the strict requirements and various application methods. Our technical specialists will be glad to analyse the current application process and provide the samples of the more advanced and cost advantageous alternatives. Diveng and our team of experts in the field of powder enamels, frits and RTUs will be happy to provide you with a full and complete solution. Below, is an example of the received RTU and enamel powder coating, as well as the product provided by Diveng that allowed to customer to cut the costs and significantly improve the quality of the finished products:

|

||||

|

||||

|

||||

|

| Enamel Powder Sample |

|

|

||||||

|